The Tier Meeting Is Not Just for the Frontline

The tier meeting enables information and improvement activity to flow at all levels in a cascading fashion. We take a look at how to get it right.

The Role of Leaders Within a CI Culture

A CI culture is a critical component of any successful business. Leaders play a crucial role in ensuring it is integrated into the company at all levels.

3 Perspectives You MUST Consider for Skills Management and Development

A deep-dive into the skills management and development, alongside compliance considerations, within a continuous improvement framework.

Unlocking the Potential of Daily Tiered Meetings At Tier 1

In this blog, we explore daily tiered meetings, focusing on the tier one meeting the foundation of transforming your organisation’s improvement efforts.

Tiered Meetings – Definitions & Examples with TeamAssurance

Get to know tiered meetings – the structured recurrent meetings held at different levels of an organisation and key to managing activity problem-solving.

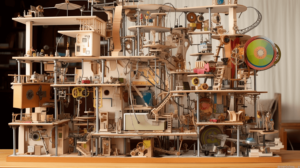

Tier Meeting Board Examples & Their Role In Lean Organisations

Access tier meeting board examples and review the best practices to get the most from your huddles at all levels. Whether frontline or topline, it’s here.

5 Ways to Boost Productivity Using Digital Lean Tools

Looking to boost productivity? Nick Strybosh shares the top 5 ways (with handy links) to do just that with the Lean tools on TeamAssurance.

How Improvement Leaders Can Set Up Continuous Improvement Frameworks

From a blank slate through to daily PDCA cycles, leaders have significant influence over the efficacy of continuous improvement frameworks.

Making Your Safety System Stack Up With Digital Tools

In this article we discuss how to standardise problem solving and root cause analysis to maximise utility of a safety system for continuous improvement.