Continuous improvement also means continuous learning. It’s never a bad idea to review your understanding of Lean to strengthen your reflexive decision making. So we’ve put together a few key items that we regularly highlight, that you should keep in mind for your improvement efforts in 2022.

Continuous Improvement Requires Discipline

True, effective continuous improvement doesn’t occur without focus and an adherence to established standards. This requires discipline – which doesn’t happen overnight. It is up to leaders to set the standard and exemplify how to make time for continuous improvement activities – as well as to regularly execute them,

As Paul Dunlop notes in a recent article,

“Lean is all about simplicity. It is about creating a workplace where the process flows, people are engaged, and leaders coach. We want to enable a particular way of thinking and ensure there is clarity on who we are and where we are going. To some this seems like a pipedream, far removed from their current situation. But, it is possible and can be achieved in a relatively short period. It just takes time, patience and most importantly discipline.”

Habits are formed through repetition; facilitating that repetition for yourself and your teams is critical. This requires you to do two things as a leader:

- Ensure your own work is structured in such a way that you can execute on your role effectively and exemplify continuous improvement.

- Identify and reinforce the standard and processes that enable performance, learning and improvement within your team.

It’s important not to think of structure and routine as constricting in this instance. Rather, they are tools to develop habits and discipline – ensuring work is completed at a set standard. Over time, this ingrained discipline enables freedom; creating space to focus on proactive, value-adding behaviour and eliminating trivial work or Lean waste.

This is achieved incrementally through a combination of established boundaries, a clear focus, and commitment to investing effort on the ‘right’ things.

Get the Message Through with Visual Management

In order to create a genuine culture of learning and improvement, it’s not enough to ensure that everyone in our organisation has access to the information required. We must also ensure that everyone can understand and interpret the available information so that we are all on the same page.

This is where visual management is incredible useful – connecting the dots for individuals, telling a story and informing their decision-making at a glance. There is great power to be harness by visual tools – you just need to ensure that they are used correctly. Distilling visual tools down to the simplest form we can for their intended purpose will maximise their effectiveness.

Some things to consider when implementing (or even reviewing existing) visual tools:

- Some team members may not speak our native tongue as a first language.

- There may be varying degrees literacy and numeracy.

- Have cultural behavioural norms.

- Hearing and vision impairments or other ability challenges may play a role in how our audience interprets information.

- Not everyone looks at charts or data regularly – ensure there is supporting context provided.

As usual, creating a space where communication flows freely amongst your teams, will enable you to best understand the needs of your audience. When they are fully engaged. connect with the visual tools and understand their necessity we are best placed for continuous improvement success.

Of course, this isn’t a ‘set and forget’ operation.

Remember to regularly review your visual management tools to ensure they are providing useful information and facilitating everyone’s work.

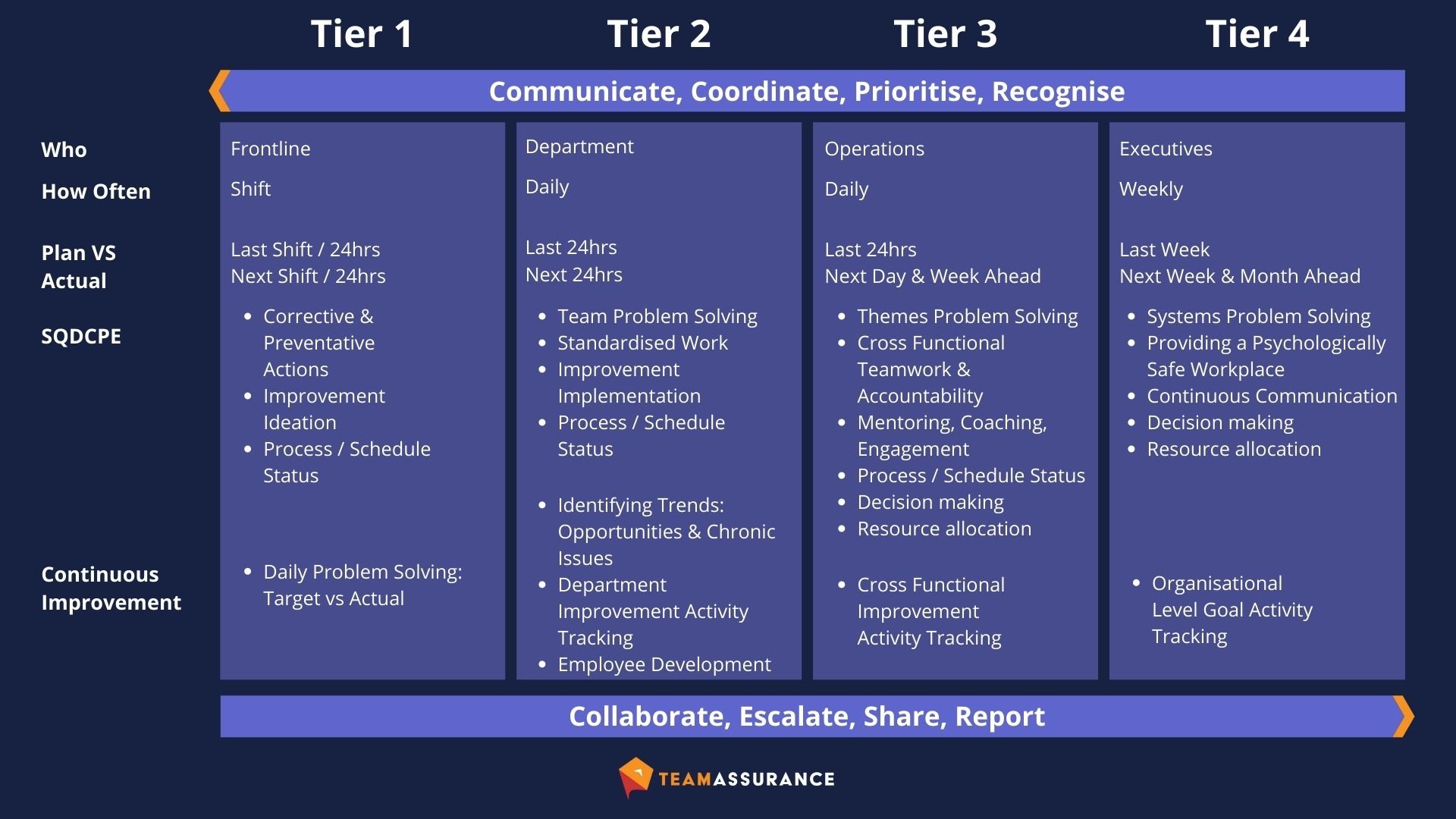

Lean Daily Management Systems Start With Tiered Meetings

All of the above leads to this key fact – you need a Daily Management System (DMS). We’ve said it multiple times, but it bears repeating: Traditional modes of top-down communication – email, meetings, intranet – are built for deskbound workers. They are not effective or practical for the 80 percent of the global workforce that don’t sit at a desk. The design and format of a DMS allows information to be swiftly communicated across teams, through the site hierarchy and between sites.

If you don’t have a clear DMS established in your organisation – you’re operating with one hand tied behind your back (perhaps even both)!

At a minimum all of your teams should be engaging in a huddle regularly, with visual reporting at the centre of the discussion and the physical group itself. These huddles should be split by tiers to ensure the right information reaches the right audience at the right time.

Now we might be a bit biased and recommend that you utilise a Virtual DMS platform like TeamAssurance – but even if it’s physical charts you’re using, don’t skip the huddle.

Different tiers of operation require different cadences and foci for their catchups. That’s up to you to decide, but here’s a starting point:

Remember to think of the system holistically – anything discussed in a huddle needs to flow up, down and across tiers. There needs to be a way to share information to other tier meetings in real-time, with rich context. That includes text, photo, video, root-cause analysis and any related activity. Without this interconnectivity you don’t truly have system merely disparate, siloed inputs – that puts you back at square one.

This is where that digital system we know a thing or two about can significantly accelerate communication, boost productivity and turn business knowhow into a competitive advantage.

Improvement is Incremental

Whenever we discuss improvement projects, we always stress that change happens incrementally. Sometimes those increments are large, but more often than not, they are small daily changes. Make time in your day to reflect and work on process rather than in the process. Even if it’s a small amount of time each day in relation to your other work, start by giving some time for full focus on continuous improvement activities.

When you look back at the end of a week, month, or the year you’ll see the material impact of that effort.

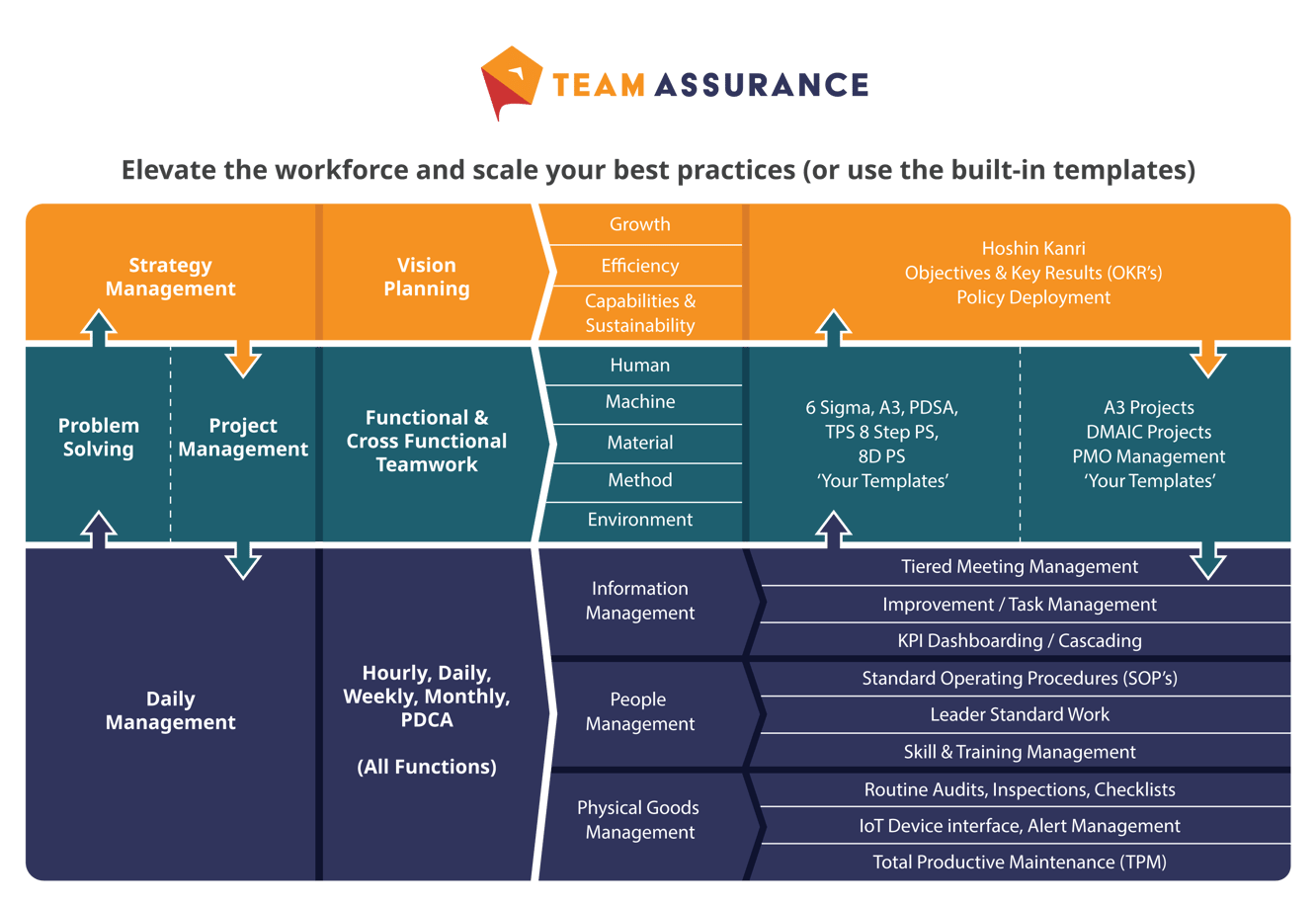

Consider Lean Tools Within a Greater C.I. Framework

For any processes to not only be sustained, but to thrive, it must be supported by adjacent processes and systems. When implementing Lean tools consider how they interconnect – and ensure you don’t optimise or develop them in isolation. Core tools like Leader Standard Work, standardised problem solving techniques, and a Tiered Daily Management system should work together to handle the full PDCA loop. This is by no means an exhaustive list; developing with the whole framework in mind allows organisations to get the most from their investment in Lean.

The schematic below of the TeamAssurance platform below shows how we designed an interconnected platform that avoids disconnected ‘Point Solutions’ (digital or analog) that do not help, and or even act as barriers, to achieving an optimised CI framework.

Want to explore the opportunities offered by digital-aids to Lean tools? If you’re a Business in need, or a Consultant with clients in need, contact us for a demonstration of the TeamAssurance platform today.

Want to explore the opportunities offered by digital-aids to Lean tools? If you’re a Business in need, or a Consultant with clients in need, contact us for a demonstration of the TeamAssurance platform today.